Under the facilitation of Lloyd’s Register, the function of the HyMethShip-system was tested for safe operation in a 3 days online workshop of all partners.

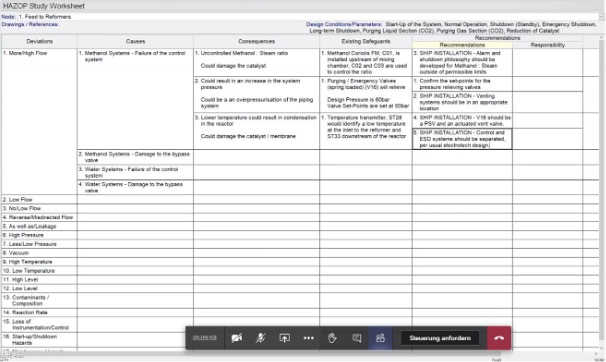

The aim of the workshop was to complete a review of the HyMethShip systems to identify any potential operability issues with the system that could impact the safety of it. The team proceeded according to the HAZOP-method. This methodological technique is used to identify hazards and operational issues associated with a process or with the integration of a design into another system, like the HyMethShip-system into a vessel.

The pre-condition to perform a HAZOP-study is that the system is already engineered. So, the HyMethShip HAZOP was based on the Demonstrator-design of TU Graz (Work package 10) and on the vessel integration design of SSPA (Workpackage 9). System layout and arrangement was provided per drawings. The HAZOP study assumes that all equipment is installed, operated and maintained according to OEM recommendations and relevant legislation. So, normal operation was considered, but also possible abnormal and emergency conditions and scenarios were considered.

The principal objectives of the HAZOP Study are to identify:

– Integration and operability hazards associated with the HyMethShip system (what can go wrong and how), including the resulting consequences.

– The existing safeguards and mitigation measures, currently in place, and make recommendations where the level of risk could be further mitigated or reduced.

The HyMethShip systems was divided into the same nodes as in the HAZID study: the feed stream to the reformers, the permeate stream, the retentate stream and the heating system (thermal oil system). For each node, the team started identifying possible deviations of elements (e.g. sensors, lines, etc.) within the node. For all deviations that were found, the causes were established. Then the consequences were sought that resulted in harm to persons or releases to the environment. Safeguards that were already provided within the design were considered subsequently, their robustness was discussed and their suitability. If the existing design was deemed not robust enough or suitable to prevent any harm, a re-design was proposed as a follow-up action. The expected likelihood and frequency of each consequence was discussed and a risk rating assigned to it. Finally, recommendations were suggested, e.g. if any further information or studies on the design or on safeguards are required.

It became apparent that the system is already well elaborated. The team assumes that it can be run safely and that this can be demonstrated with a successful operation of the Demonstrator.